It’s (Bio)Logical to Focus on Biologicals Now

I learned to keep going, even in bad times.

I learned not to despair, even when my world was falling apart.

I learned that there are no free lunches.”

I know nothing about cars, but I do know that Biological Solutions have a critical role to play in the future of our sustainable food production, especially in Africa. It is the future direction, and only direction, of Agriculture in our country.

To do this well, we need an ecosystem of partnerships who deliver quality and effective solutions, honour exceptional custodianship, stewardship and transfer of knowledge. At Andermatt Madumbi we look to partner with like-minded champions who share our passion for changing the future with wisdom and insight.

Flying home to South Africa, I was filled with pride for our beautiful country, despite the challenges, for the resilience of our people and the future we need to believe in. At Andermatt Madumbi we commit to being a part of the solutions for our future focused farmers. A new generation, who share our vision for a future with healthy food and healthy environment, for all.

Michelle Lesur

CEO Andermatt Madumbi (Pty)

WELCOME TO THE TEAM

Ortwin du Plessis

Biospecialist in Training

We are delighted to welcome Ortwin du Plessis to the Andermatt Madumbi team.

Favourite Quote:

Do the best you can, until you know better. Then when you KNOW better. DO BETTER! – MAYA ANGELOU

Ortwin joins the team as a Regional Biospecialist, Northern Cape and Western Free State. His main focus will be irrigated crops such as potatoes, pecans, maize, wheat and onions. He will also support dryland maize and soya growers in the region. Ortwin lives in the Hartswater region, with his wife and young family.

‘On meeting Ortwin you will immediately be drawn to his energy, ambition and passion for agriculture. We believe Andermatt Madumbi provides an ideal platform for him to make the difference he aims to realise. Together we look boldly to the future, because we know we can change it. Welcome Ortwin.’ – Michelle Lesur, Andermatt Madumbi CEO

NEWSFLASH

New communication platform Andermatt Madumbi Podcast studio launched!

Knowledge is power.

At Andermatt Madumbi, we are committed to sharing our insight and expertise with partners, growers and all persons interested in learning more about biorational solutions, and their role in contributing to the way food is grown.

We are delighted to share that the Andermatt Madumbi Podcast Studio, located at our head office in Hilton, KwaZulu-Nata, is up and running! We look forward to sharing our recordings on our website and through Spotify, with more platforms for you to enjoy our podcasts planned for the future

Please select your favourite platform and revert with feedback to support us in improving this new service.

We look forward to creating a database of meaningful bio discussions to support all growers on their journey to growing healthier, stronger crops.

‘Healthy Food and Healthy Environment, for all’

CFU’s GOT YOU CONFUSED?

Head of Research at Andermatt PHP

Explaining spore counts, germination percentages and CFU’s (colony forming units).

Spore count, germination percentage and colony forming units (CFUs) are measures that indicate the quantity and the viability of the active ingredient within a biological product to ensure that each batch meets the standards specified on the product’s label.

The spore count is a measure of quantity (number of spores), and the germination percentage is a measure of viability (percentage of alive spores). CFU is a measurement of the quantity of viable active ingredient.

In South Africa, Andermatt PHP products are currently registered with the spore count per gram provided on the label. However, each batch undergoes a germination percentage test as well as a CFU count in order to ensure the correct quantity of viable active ingredient is present in each batch.

Spore count – Quantity of active

Spore count – Quantity of active Spores are individually counted at 400 times magnification. The guaranteed minimum for final product for Eco-Bb® is 2 x 109 (or two billion) spores per gram. The spore count cannot change over time, only the viability of each spore (whether it is living or dead).

Microbe Definition:

‘a living organism that on its own is too small to be seen without a microscope’

Germination – Viability of active

A germination test is done by suspending the final product in sterile water and growing it on enriched media. After 24 hours the spores are viewed at 400 times magnification and individual germinated spores are counted as a percentage of total spores counted (Fig. 1).

Figure 1: Spores of Beauveria bassiana shown with two spores germinating with germ tubes and ten ungerminated spores (x400 magnification).

Germination – Viability of active

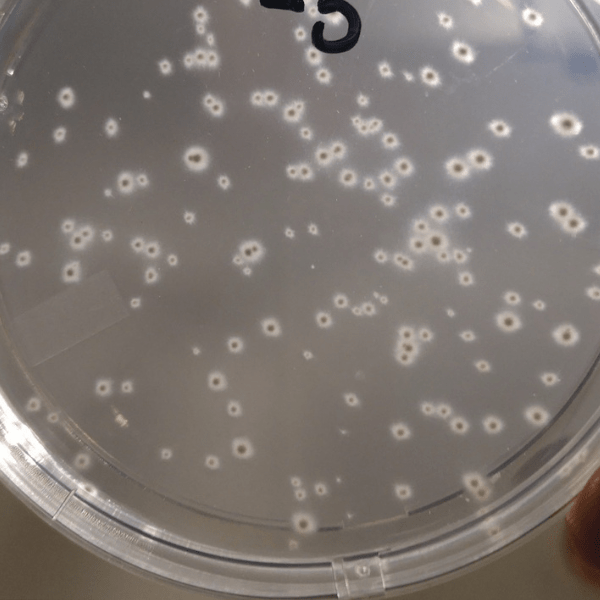

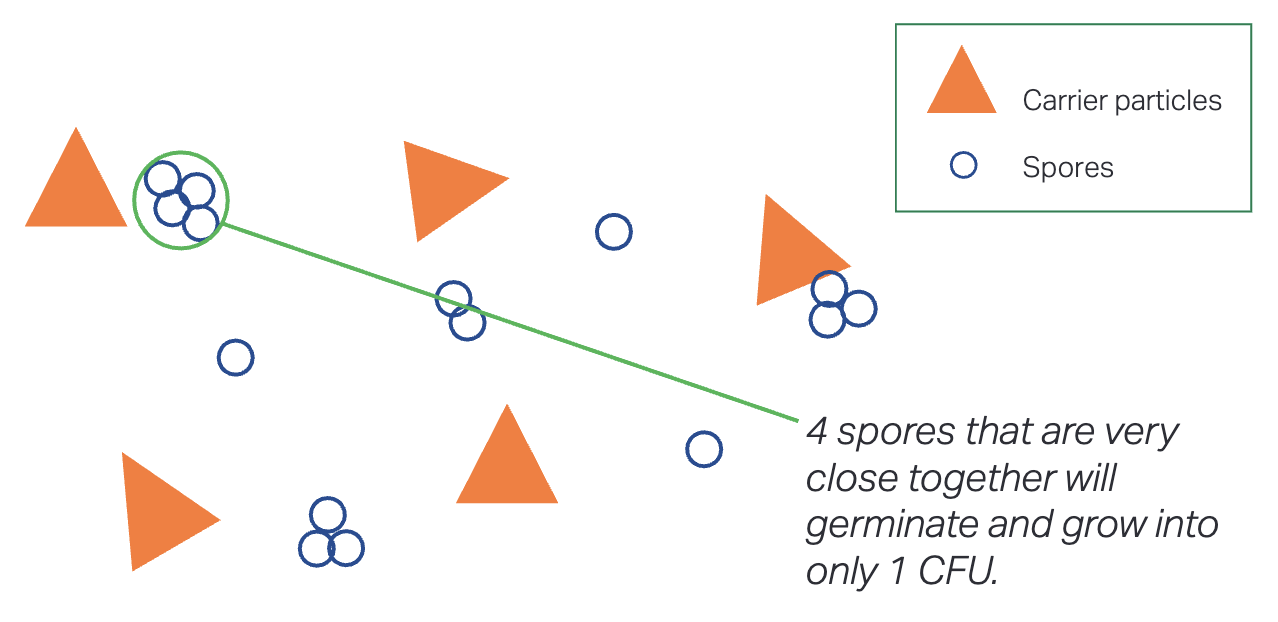

CFU’s are quantified by suspending the final product in sterile water and growing it on enriched media. The growth of spores is left for 3-4 days until individual colonies are visible with the naked eye and can be counted (Fig. 2).

Figure 2: Colony forming units (CFU) as seen on agar.

Figure 1: Spores of Beauveria bassiana shown with two spores germinating with germ tubes and ten ungerminated spores (x400 magnification).

Eco-Bb® contains Beauveria bassiana. Reg. No. L8469, Act No. 36 of 1947. Andermatt PHP (Pty) Ltd, PO Box 207, Nottingham Road, 3280. Reg. No. 2003/007987/07.

FAQs

Is a product with a higher active ingredient concentration better than a product with a lower active ingredient concentration?

No – the concentration of a particular isolate in a product (the active ingredient used in different products) is dependent on the virulence of the isolate. Virulence is the harmfulness of an organism towards another (e.g. the harmfulness of Beauveria bassiana towards a red spider mite). The higher the virulence of the isolate, the lower the amount of isolate needed to kill its target. During product development, multiple strains are compared against each other for virulence and the dose required to kill its target. Once the product is formulated at a given concentration, it is tested in multiple field trials at various dose rates to determine the minimum effective field dose. Therefore, a registered product has been scientifically tested to ensure that the correct field dose rate for the product is indicated on the label.

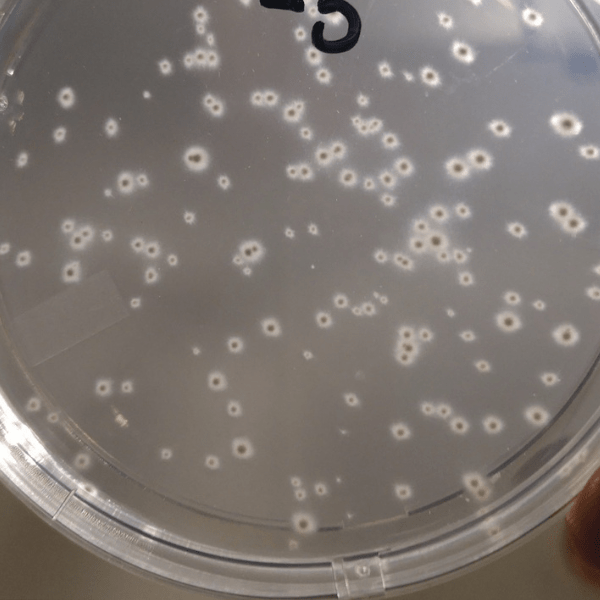

For Eco-Bb®, why is the CFU/g lower than the spore count/g?

Eco-Bb® is formulated with oil so that multiple spores are encapsulated within each oil droplet. Therefore, when Eco-Bb® is placed on growth media, several spores together will grow into only 1 colony forming unit (see figure 3 below of spores in oil). An average CFU count for this product is 1 x 108 (hundred million) CFU per gram. Oil is used in the formulation to protect the spores from UV and desiccation, and to allow the spores to suspend in water when applied to the spray tank.

Why does spores/g appear on the Andermatt PHP product labels and not CFU/g?

At the time of registration, spores/g was the standard measure to indicate the concentration of the active ingredient in a fungal based product. Although germination percentage and CFU/g are not indicated on our labels, these tests are conducted on each batch to ensure that a high-quality product reaches our customers every time.

Why is spore count, germination and CFU important?

These measures provide quality control targets that production companies must meet to ensure that each batch of a particular product received by the customer is of the required standard.

Chantal Janks

Head of Research at Andermatt PHP

Please select your favourite platform and revert with feedback to support us in improving this new service.

We look forward to creating a database of meaningful bio discussions to support all growers on their journey to growing healthier, stronger crops.

‘Healthy Food and Healthy Environment, for all’

ECO-Bb IN THE SPOTLIGHT

Technical Development Specialist

Targeting Two Pests with One Biosolution

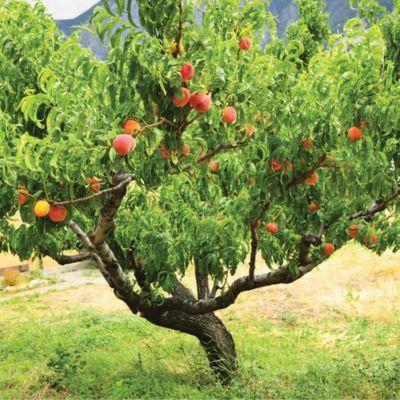

Stone fruit has been the pioneer in the South African export fruit market since 1892 when the first 14 cases of peaches arrived in England with less than 5% decay, selling at an astounding price.

Since then, the South African stone fruit industry has grown and currently produces on average 350 000 tons per year. However, the stone fruit industry has been hit hard in the past few seasons and the industry will have to refocus and regain momentum ahead of exporting this season.

Amongst other factors which play an important role in the export of stone fruit are the phytosanitary pests, namely false codling moth (FCM) (Thaumatotibia leucotreta) and red spider mite (Tetranychus urticae).

Stone fruit has been the pioneer in the South African export fruit market since 1892 when the first 14 cases of peaches arrived in England with less than 5% decay, selling at an astounding price.

Since then, the South African stone fruit industry has grown and currently produces on average 350 000 tons per year. However, the stone fruit industry has been hit hard in the past few seasons and the industry will have to refocus and regain momentum ahead of exporting this season.

Amongst other factors which play an important role in the export of stone fruit are the phytosanitary pests, namely false codling moth (FCM) (Thaumatotibia leucotreta) and red spider mite (Tetranychus urticae).

False Codling Moth

(Thaumatotibia leucotreta)

False codling moth females lay their eggs on the skin or rind of the fruit and, within six to twelve days, the larvae hatch, and bore into fruit. The larva completes its life stages within the fruit before it drops to the soil to pupate. Infested fruit also drop to the floor, thereby also directly impacting the yield.

Red Spider Mite

(Tetranychus urticae)

Red spider mite flourish in the warm weather of the Western Cape, especially when trees are under stress. Red spider mite populations increase significantly during hot, dry weather, and can complete a full life cycle within 14 days when average daily temperatures are above 25°C. Leaves infested with red spider mites become mottled and are covered by fine webbing

The mites disrupt the photosynthesis process, and eventually the leaves will wilt and die. Even though red spider mites prefer the underside of leaves, they also move to the fruit during severe infestations, causing the fruit to become speckled.

A Biological Solution

Since both pests cause serious economic loss for the stone fruit industry, and FCM carry phytosanitary risks, it is vital to build a strong Integrated Pest Management (IPM) program. Eco-Bb® (active: Beauveria bassiana) is a registered biological control product focusing on the suppression and population control of both red spider mite and false codling moth (FCM) in stone fruit.

Eco-Bb® ® is an environmentally-friendly biological solution which can be applied up until harvest in an IPM program. Eco-Bb® suppresses pest populations which allows for the build-up and establishment of natural predators to control pests more effectively and economically.

Mode of action

Eco-Bb® has two modes of action, namely contact and ingestion, and different modes of action are involved with the suppression of different pests. When Eco-Bb® is applied to host plants spores make contact with the pest, either by direct spraying onto the insect, or indirectly as the pest crawls over the treated substrate. The spores attach to the cuticle (outer skin) and begin to germinate (Fig. 1). This mode of action is relevant to red spider mites as well as FCM. Some insects also ingest spores through feeding on treated plant material, with the spores infecting through the mouthparts of the pest. FCM larvae can ingest spores as they start to burrow into the fruit.

As Eco-Bb® spores germinate, enzymes are secreted which weaken the cuticle and the appressorium penetrates the pest’s body. The fungus continues to grow internally, feeding on the pest’s internal organs. The pest stops feeding and can die within 3 to 5 days. The fungus grows out through the cadaver to sporulate, producing more spores and a continued source of inoculant for other pests. Figure 2 (Fig.2) illustrates Eco-Bb® spores attached and germinating on a false codling moth larva.

Figure 2. The cadaver of a false codling moth larva treated with Eco-Bb®, covered in and producing Beauveria bassiana spores.

Eco-Bb application recommendations:

- Full cover application.

- Dose rate of 600 to 1000 g/ha.

- Minimum of three applications are required for optimal suppression.

- 7 to 14-day intervals (depending on pest population pressure).

Contact our trained Bio-specialist in your area to find out how Eco-Bb® can be incorporated into your current IPM program.

Author:

Nastassja Viljoen

Technical Development Specialist, Andermatt Madumbi

GLOBAL EVENTS

BRONZE SPONSORSHIP 10 TGIS

10th International Table Grape Industry Symposium, Somerset West, November 2023.

Through the power of the collective expertise within the global Andermatt group, we bring you the best the world has to offer in innovative and sustainable biological solutions.

Thank you to our participating subsidiaries for making this sponsorship a reality.

- Andermatt BioControl Suisse, Switzerland

- Andermatt do Brasil

- Andermatt PHP, South Africa

- AbiTep, Germany

- Biofa, Germany

ANDERMATT AFRICA CONFERENCE – MAY 2023

The Andermatt in Africa conference was held at Enashipai Hotel, Naivasha, Kenya from 8 – 10 May 2023.

Andermatt’s vision for Africa is focused on feeding the continent sustainably, as well as strengthening African economies through the export of high quality, residue-free, healthy food.

The key discussion topics were rooted in the successful integration of biological solutions into existing integrated pest management (IPM) systems. Emphasis was placed on the need for these to be ‘farmer friendly’ with regards to application methods, efficacy, quality and value. Future solutions are essential to the future of all markets and within the Andermatt group the pipeline is strong.

The final day was allocated to farm visits and the delegates relished the opportunity to learn more about agriculture in Kenya. A highlight was the site visit to the Andermatt Kenya Macrobial production site and demo from the host team. Demo trials featuring 10 different locally grown crops, using a range of different crop production inputs attracted much attention and discussion – the proof is in the pudding as they say.

The team also had the privilege to visit local growers to engage with the technical and commercial teams on key challenges and opportunities. We’d like to extend our sincere thanks to Ol Njorowa Rose Farm, Stokman Kenya Production Nursery and Royal De Ruiter Rose Breeders for hosting our team.

‘Ultimately, as Andermatt we must be farmer led. It is up to our collective teams to champion future biological farming solutions, providing a ‘toolbox’ of credible natural solutions, in a world demanding the same.’– Hamish Ker, Commercial Manager: Kenya and Eastern Africa.

The Andermatt in Africa conference offered the ideal platform to realise the power of the collective expertise within the global Andermatt group. We are proud to bring African growers the best the world has to offer in innovative and sustainable biological solutions.