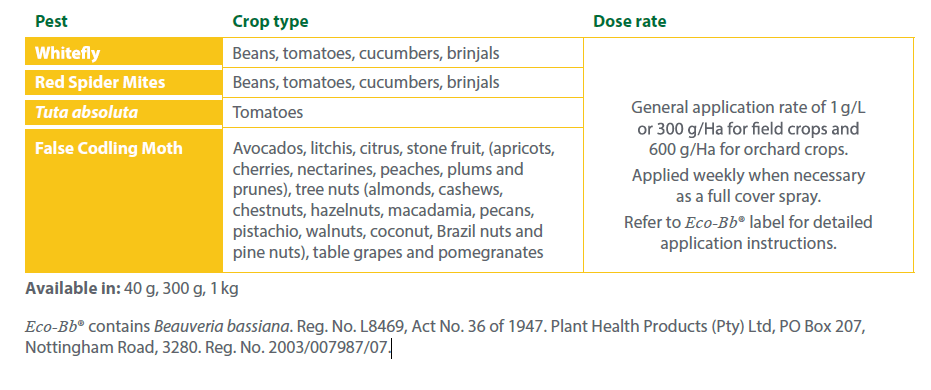

PRODUCT FORMULATION

How is Eco-Bb® formulated?

Eco-Bb has a unique dry powder formulation, which includes oil-coated Beauveria bassiana spores. The product is non-toxic, has no with-holding period and is approved for organic use. The oil coating helps protect the spores from UV damage and desiccation. Multiple spores are contained within each oil droplet, which enhances the virulence of Eco-Bb® against the insect or mite pest.

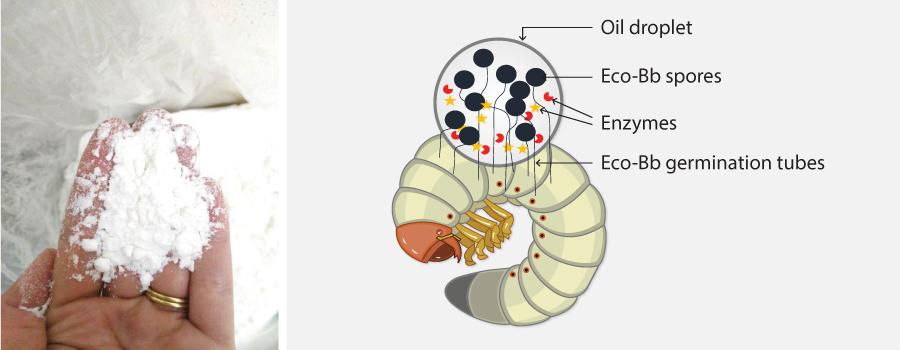

How does Eco-Bb® work?

Once the oil droplet lands on the insect pest, the spores germinate and produce enzymes, which penetrate the insect’s cuticle. The Eco-Bb® fungus then grows inside the insect pest, which changes insect behaviour and reduces feeding, before causing death to the insect. Death of the insect will typically occur 3 to 5 days after initial contact with Eco-Bb®.

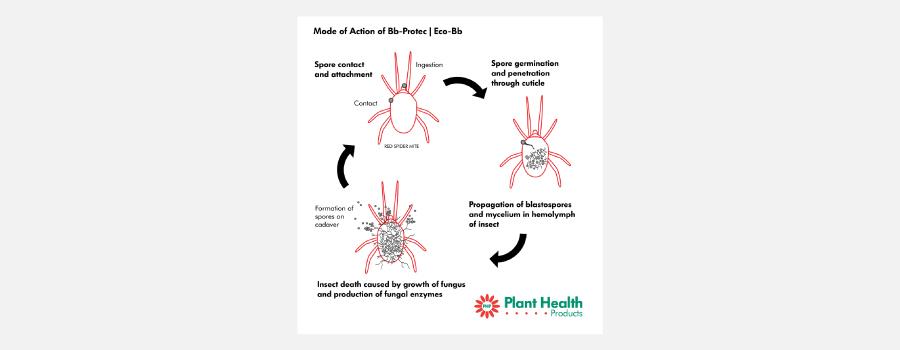

QUALITY CONTROL

How does PHP ensure that every batch of Eco-Bb® meets a

high quality standard?

Multiple quality control steps are undertaken throughout the production process, which ensures that every batch of Eco-Bb® meets a high-quality standard. These steps include:

- Bioassay – A bioassay is performed by applying the fungus to an insect within the Eco-Bb® host range. The insect is monitored to confirm that Eco-Bb® caused its death.

- DNA sequencing – DNA sequencing is conducted by an external laboratory to confirm that the correct microorganism (Beauveria bassiana) is included in the production process.

- Spore count – A spore count is performed to ensure that every batch of product is formulated with a minimum of 2×109 spores per gram.

- Germination test – A germination test, which is a measure of the % of spores that germinate, is performed to ensure that the Eco-Bb® spores are viable. This is undertaken on every batch both before and after product formulation.

- CFU test – A CFU test is performed on each batch of the formulated product to confirm the concentration of viable Eco-Bb® units per gram of product.

- Bacterial limit and human pathogen testing – A bacterial limits test and human pathogen test is performed on each batch of the formulated product to ensure that Eco-Bb® complies with microbial quality and human health standards.

Eco-Bb® production process and associated quality control measures

Eco-Bb® SHELF LIFE AND CORRECT STORAGE

How should Eco-Bb® be stored?

The optimum storage condition for Eco-Bb® is 4°C – 10°C. At this temperature, the product is expected to have maximum shelf life; the current registered shelf life is 12 months. Refer to the label for the batch expiry date at the expected storage conditions. In warehouses and consignment depots, stock is stored at 4°C; however, when in transit Eco-Bb® is not in a refrigerated environment because this transit period is usually less than 7 days.

Once opened how long can I keep Eco-Bb® ?

Once the product packaging has been opened, the spores are exposed to moisture fluctuations. This will affect the viability of the product slowly over time. The product will still be fully viable for one month after opening.

Can Eco-Bb® be frozen?

Eco-Bb® can be frozen once, but must be used soon after thawing and not frozen again once it has thawed.

What happens if the Eco-Bb® is exposed to elevated temperatures?

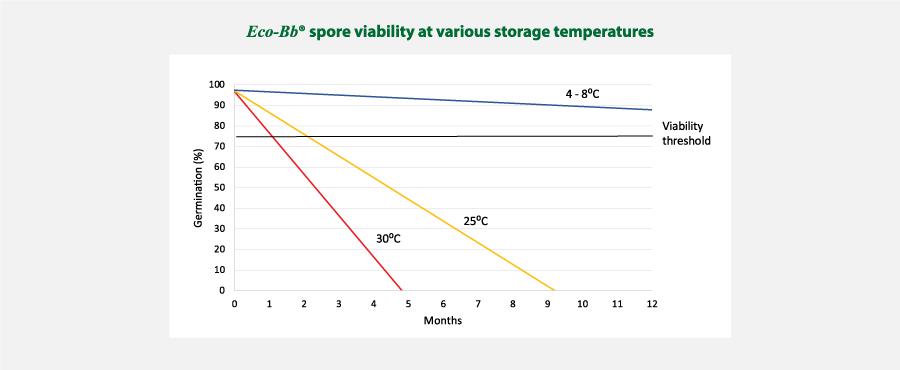

In an experiment, Eco-Bb® was stored at various temperatures for an extended period in a controlled environment. During this time, the product was tested regularly for viability in the form of a germination test. This was to establish the reduction of spore viability when exposed to different temperatures and therefore the quality of the product.

The 25°C and 30°C results illustrate the potential effects of extended temperature exposure on the shelf life of the product. Daily temperatures would naturally fluctuate, so these results represent a worse case scenario of exposure. Responsible transport and short-term exposure to adverse conditions (not exceeding 35°C) will not affect the long-term storability and efficacy of the product.

PRODUCT APPLICATION

How should Eco-Bb® be applied?

For the best results when using Eco-Bb®, please consider the following:

- Eco-Bb® is a contact insecticide and therefore the best efficacy is achieved when Eco-Bb® makes direct contact with the target insect.

- Good spray coverage is essential. The best results are achieved using a mist blower.

- Ensure that areas where pests are found habitually are covered. i.e. on the underside of the leaf and leaf folds.

- Where possible, apply the product in the late afternoon when humidity is high and UV is low, unless the target insect/life cycle stage is only active during the early morning.

- Avoid the use of broad-spectrum fungicides for at least 3 days before and 3 days after Eco-Bb® applications. Consult your sales representative for a list of compatible and incompatible products.

- Tank pH must be maintained between 4 and 12.

- Eco-Bb® is compatible with non-ionic silicone-based surfactants. Surfactants and other adjuvants should be used only when recommended.

- The product must be used within 1 month of opening. The 12-month shelf life is only guaranteed in sealed packaging under the recommended storage temperature.

DISCLAIMER: Although this inoculant has been tested under a variety of conditions, the supplier does not warrant that it will be efficacious under all conditions. Because the active agent is a living organism, its action may be affected by storage, handling, climate or soil conditions. This naturally occurring organism should not cause damage to crops, vegetation, or the environment, nor harm to man and animals. However, in the unlikely event of this happening, the supplier does not accept responsibility for any damage that may occur.

COMPATIBILITY TESTING

Eco-Bb® is compatible with baculovirus products, IPM and organic programmes. Before mixing Eco-Bb® with other pesticides and fungicides, consult the compatibilities list or contact your sales representative. Eco-Bb® contains a live fungus and therefore it is at risk to being damaged by broad-spectrum fungicides.

How do you know if Eco-Bb® can be tank mixed with another product?

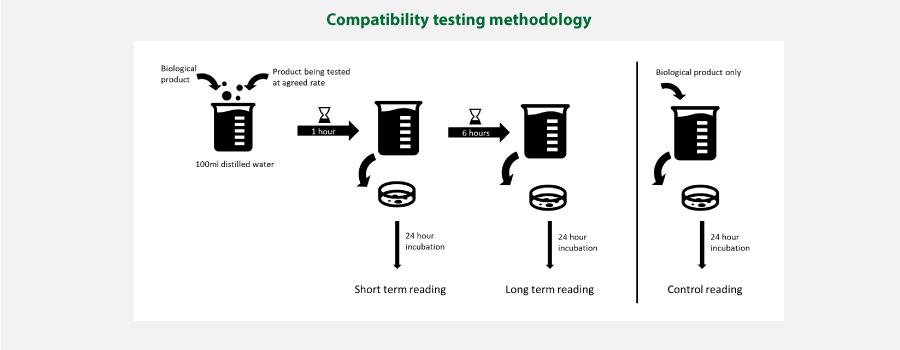

PHP conducts compatibility tests to determine whether Eco-Bb® can be used together with another product. A tank mix with Eco-Bb® and the test product is simulated in the laboratory at the predetermined rates. The solution is then extracted and placed on growth media after 1 hour and again after 6 hours. Each sample is incubated for a period of 24 hours, after which the samples are examined.

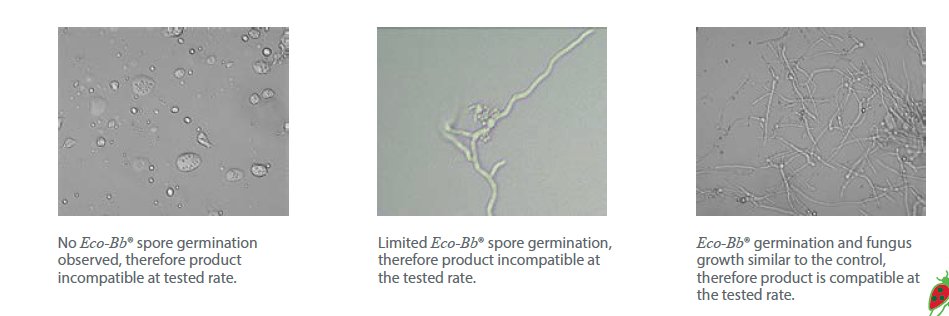

How are the compatibility test results interpreted?

Each sample is examined and compared to the control to determine the effect of the test product on Eco-Bb® spore germination and growth. Incompatible products either kill the Eco-Bb® spores, so that they do not germinate, or they damage the Eco-Bb® spores, so that the fungus does not grow as expected under favourable conditions. Completed results are uploaded onto the compatibility sheet and updated regularly. Contact Madumbi Sustainable Agriculture for the latest compatibility results.

BENEFICIAL INSECTS

Does Eco-Bb® negatively effect beneficial insects and bees?

Eco-Bb® has been tested on various local and international laboratories to determine its effect against beneficial insects.

Green lacewing, Predatory Wasps, Ladybirds

GLP accredited laboratories in the USA conducted studies which concluded that Eco-Bb® does not harm:

- Green lacewing (Chrysoperla rufilabris)

- Predatory wasps (Pediobius foveolatus)

- Ladybirds (Lindorus lopanthae)

Predatory wasps and predatory beetles

Biobee Laboratory in South Africa tested Eco-Bb® that it is harmless to both a predatory wasp (Anagyrus sp. Nr. Pseudococci) and predatory beetle (Cryptolaemus montrouzieri) specie.

Honeybees

Applied Insect Science, a British GLP-accredited laboratory, tested Eco-Bb® on honeybees. Both a contact (product applied to the body of the bees) and an oral (product fed to the bees) study were undertaken and determined the following:

Honeybee contact study:

This study was conducted by exposing honeybees to 100x the maximum field dose rate of Eco-Bb®. The researchers did not find a significant difference in the mortality between the treated group and the untreated control group. Therefore, Eco-Bb® is not harmful to honeybees on contact.

Honeybee oral exposure study:

The oral exposure study was conducted by feeding the bees Eco-Bb® at 100x the maximum field dose rate. This treatment was found to reduce honeybee survival, however, it is unlikely that bees would ever encounter this dose rate in the field. In addition, less than 50% of treated bees had died by the end of the 30 day study period and therefore the median lethal time (the amount of time it takes for 50% of the population to die) could not be calculated.

PRODUCT PERFORMANCE AND BENEFITS

How does Eco-Bb® perform?

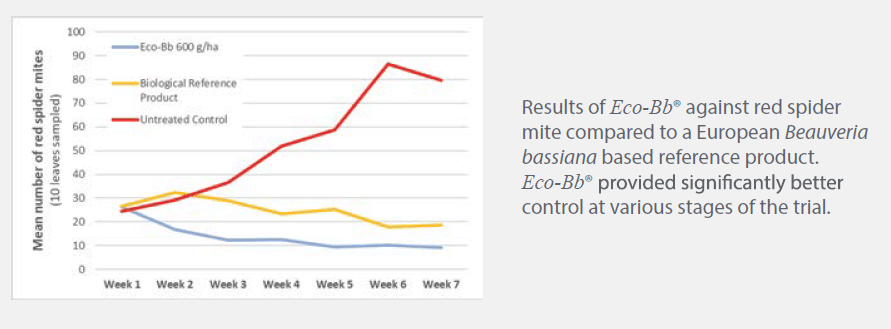

Eco-Bb® provides effective control against various insect pests, including red spider mite, whitefly, woolly whitefly, mealybug and false codling moth. It has successfully been used on a range of crop types, in different conditions around the world. It targets all insect life stages and therefore it is able to reduce the target pest population at various levels.

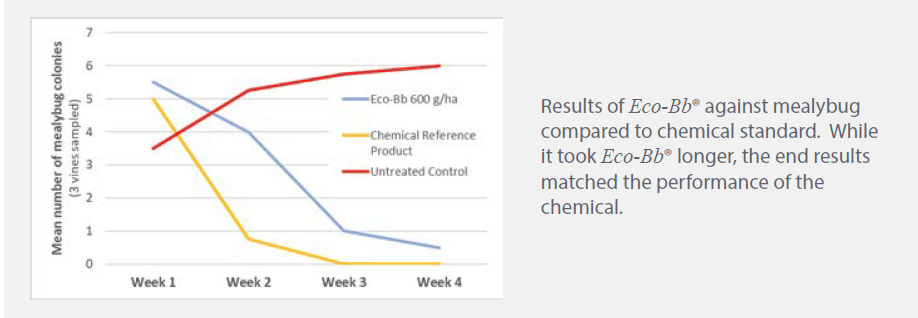

It is important to note that a biological control product, such as Eco-Bb®, does not have an overnight knock-down effect on insects as with a chemical insecticide, but is effective over time in weakening and eroding insect populations. Therefore, preventative control to manage pest populations is recommended.

Eco-Bb® is compatible with virus-based products, which strengthens overall biological control and IPM programmes by combining different modes of action.

Eco-Bb® has been tested in various conditions in South Africa, Europe, America, Canada and Asia and performs well against other internationally produced Beauveria bassiana based products.

Eco-Bb® FATE IN THE ENVIRONMENT

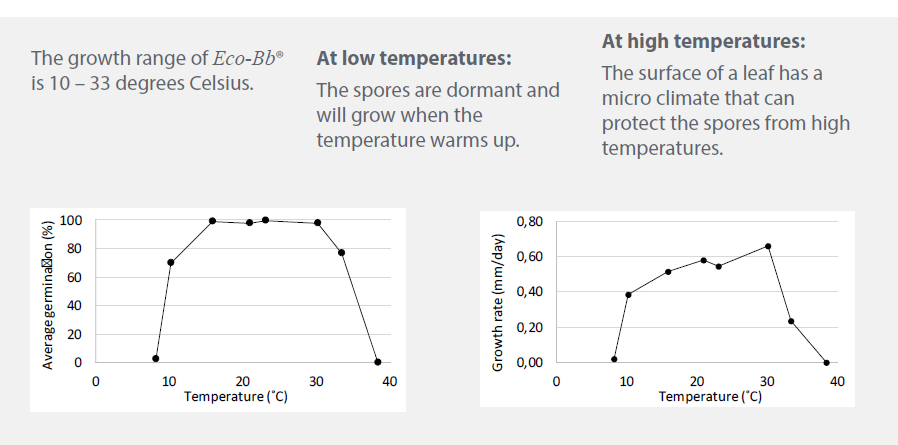

At what ambient temperature will the product work?

The percentage germination of Eco-Bb® spores at different temperatures, as well as the rate of growth at each temperature, was tested in the laboratory.

How well does the product survive after application?

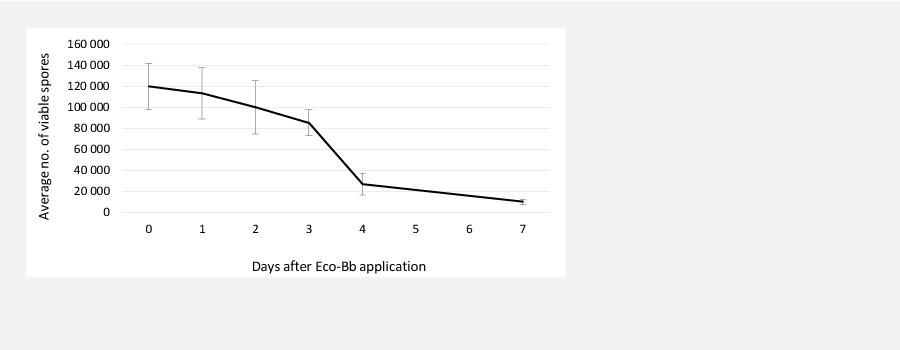

Eco-Bb® was applied at the highest dose rate to a number of fruiting tomato plants in a polytunnel. The fruit was then sampled on the day of application and each day following to determine the amount of product that remains on the fruit over time.

Results: From the time of application to 3 days after application, the number of viable spores remained stable. A significant decrease in the number of viable spores was observed between days 3 and 7. However, viable spores were still detected in low numbers up to 7 days after application.

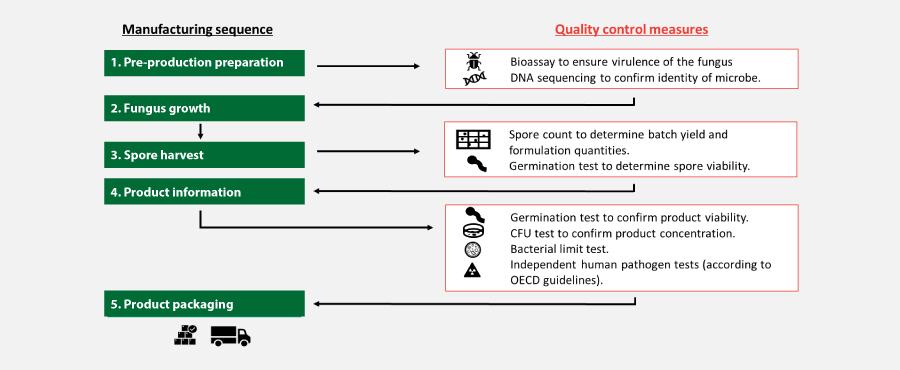

Registered uses: